Planning without considering time: a frequent error

- marco ferrari

- Jul 22, 2021

- 2 min read

During the analysis phase of an MPS/MRP project, I frequently find companies making a planning without considering the time. This is most frequent when they are using old or very basic softwares. For this reason they ask me to add fields on some pages so that they can continue to work in the same way as in the past. Let's try to understand what does it mean and why this way to do planning is wrong and risky.

Planning without considering time means to do a very simple calculation:

Final Inventory = Inventory + Inbounds - Outbounds

When Final Inventory is negative I need to buy, otherwise not.

Let's have a look at an example in Business Central.

If we make the above calculation in this case, it seems we don't need to do anything because Final Inventory is positive:

Final Inventory = 9 + 30 - 18 = 21

In this specific case, at the end of all sales we'll have 21 PCS in inventory of this item.

By taking a look at the Projected Available Balance, we discover that the situation is different, because in some periods the value is negative: this means that the company will not be able to ship in time:

The problem is due to the fact that the purchase order is in late.

The MPS/MRP engine would generate a warning in this case, with some suggestions depending on the planning setup of the item. The basic warning would be to advance the purchase order and possibly to reduce the quantity to 9 PCS instead of 30. This would fix the problem.

But even when the Projected Available Balance is correct the absolute caclulation is wrong: the risk is to buy too much in advance. This calculation does not tell you when the item will be shipped, but just that you will have to ship it sooner or later. Suppose to have this:

Apparently we are in a bad situation, because Final Inventory is negative

Final Inventory = 9 + 30 - 133 = -94

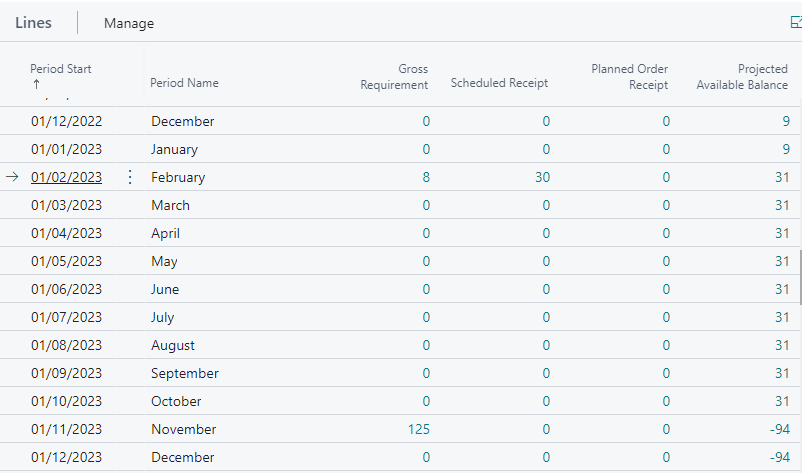

This could be translated into a wrong suggestion: buy 94 items right now. By taking a look at the Projected Available Balance we note that this would be wrong, or risky:

We discover that the negative value will be in November and not now. Buying today to cover future demand is risky, because orders can be changed or canceled.

With these examples we can understand that making absolute calculations on item availablity is not correct and is a risk for the company. By introducing the Lead time, the planning engine would suggest to buy at the right time (and in the example above, if the lead time were greater than nine months we would be in late).

Comments